- Home

- Commercial Pumps

- Standard Centrifugal Pump

- XZS Standard Centrifugal Pump

XZS Standard Centrifugal Pump

Application of XZS Standard Centrifugal Pump:

Water supply: filtration and trasfer at waterworks, regional water supply

and pressure boosting in main pipe

Industrial pressure boosting: Water system, cleaning system

Industrial water supply: boiler feeding, cooling system, air conditioning,

transportation of light acid and alkali liquid

Water treatment: distillation systems, separators, swimming pools

Agricultural irrigation, petrochemical industry, medicine and santation,

etc.

Operating Conditions for XZS Standard Centrifugal Pump:

- Thin, clean, non-flammable and explosive, not containing the liquid with solid particle and fibers

- Liquid temperature: - 15 ~ +80℃

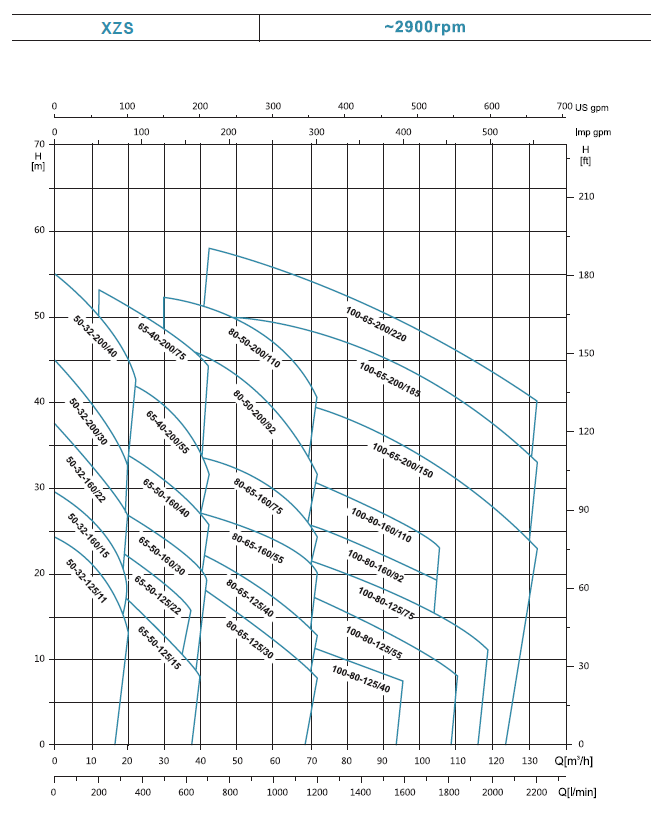

- Flow range: 0.7 ~132 m3/h

- Head range: 9 ~58 m

- Ambient temperature: -15 ~ +40℃

- Max. operation pressure: 33 bar

- Altitude: up to 1000 m

XZS Standard Centrifugal Pump Motor Features:

- IE 2 motor (IE 3 motor optional)

- Totally enclosed and fan-cooled

- Protection class: IP 55

- Insulation class: F

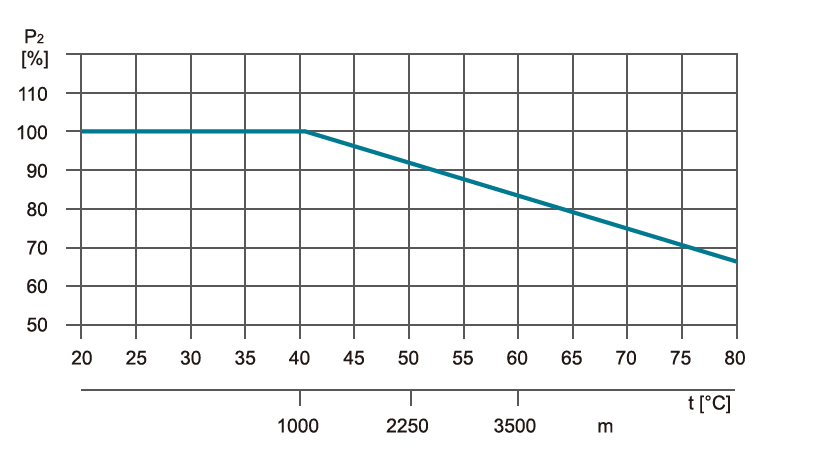

Ambient Temperature

Max. Ambient temperature: +40°C. Ambient temperature

above 40°C, or installation at altitude of more than 1000 m

above sea level, require the use of an oversize motor.

Because of low air density and poor cooling effects, the

motor output power P2 will be decreased. See the picture.

For example, when the pump is installed at altitude of more

than 3500 m above sea level, P2 will be decrease to 88%.

When the ambient temperature is 70°C, P2 will be decreased

to 78%.

| MODEL | POWER | Q (m3/h) | 0 | 6 | 9 | 12 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 | 60 | 72 | ||

| kW | HP | Q (l/min) | 0 | 100 | 150 | 200 | 300 | 333 | 360 | 400 | 450 | 500 | 600 | 700 | 800 | 1000 | 1200 | ||

| 50-32-125/11 | 1.1 | 1.5 | H (m) | 24 | 21.5 | 20.5 | 19.5 | 16 | 13 | ||||||||||

| 50-32-160/15 | 1.5 | 2 | 29.5 | 27 | 26 | 25 | 21 | 18 | |||||||||||

| 50-32-160/22 | 2.2 | 3 | 37 | 33.5 | 32.5 | 32 | 28.5 | 27 | |||||||||||

| 50-32-200/30 | 3 | 4 | 45 | 41 | 40 | 38 | 34 | 32 | |||||||||||

| 50-32-200/40 | 4 | 5.5 | 55 | 51 | 50 | 49 | 46 | 45 | 43 | ||||||||||

| 65-50-125/15 | 1.5 | 2 | 20 | 19 | 18 | 17 | 16.5 | 15 | 14 | 12.5 | 10 | ||||||||

| 65-50-125/22 | 2.2 | 3 | 26 | 23.5 | 22.5 | 22 | 21.5 | 21 | 20.5 | 19.5 | 16.5 | ||||||||

| 65-50-160/30 | 3 | 4 | 31 | 29 | 27.5 | 27 | 26.5 | 25.5 | 25 | 24 | 22 | 19 | |||||||

| 65-50-160/40 | 4 | 5.5 | 39 | 35.5 | 34.5 | 34 | 33.5 | 32.5 | 32 | 31 | 29 | 26 | |||||||

| 65-40-200/55 | 5.5 | 7.5 | 47 | 43 | 42.5 | 42 | 41.5 | 41 | 40.5 | 39 | 37 | 33 | |||||||

| 65-40-200/75 | 7.5 | 10 | 57 | 53 | 52.5 | 52 | 51 | 50 | 49 | 48 | 46.5 | 44.5 | |||||||

| 80-65-125/30 | 3 | 4 | 22.5 | 20 | 19.5 | 19 | 18.5 | 17.5 | 16 | 13 | 9 | ||||||||

| 80-65-125/40 | 4 | 5.5 | 25.5 | 23 | 22.5 | 22 | 21.5 | 20.5 | 20 | 17 | 13.5 | ||||||||

| 80-65-160/55 | 5.5 | 7.5 | 33 | 29.5 | 29 | 28.5 | 28 | 27 | 26 | 24 | 20 | ||||||||

| 80-65-160/75 | 7.5 | 10 | 39 | 36 | 35 | 34.5 | 34 | 33.5 | 32.5 | 29 | 24 | ||||||||

| 80-50-200/92 | 9.2 | 12.5 | 53 | 48 | 47.5 | 46.5 | 44.5 | 39.5 | 34 | ||||||||||

| 80-50-200/110 | 11 | 15 | 57.5 | 53 | 51 | 50.5 | 50 | 47 | 41 | ||||||||||

| 100-80-125/40 | 4 | 5.5 | 20 | 17.5 | 16.5 | 15.5 | 14 | 12 | |||||||||||

| 100-80-125/55 | 5.5 | 7.5 | 23 | 21.5 | 20.5 | 20 | 18 | 16 | |||||||||||

| 100-80-125/75 | 7.5 | 10 | 29 | 27.5 | 26.5 | 25.5 | 23.5 | 21.5 | |||||||||||

| 100-80-160/92 | 9.2 | 12.5 | 33 | 31 | 30 | 28 | 26 | ||||||||||||

| 100-80-160/110 | 11 | 15 | 38.5 | 36 | 35 | 33 | 31 | ||||||||||||

| 100-65-200/150 | 15 | 20 | 47 | 44 | 43 | 41 | 39 | ||||||||||||

| 100-65-200/185 | 18.5 | 25 | 53 | 51 | 50 | 49 | 48 | ||||||||||||

| 100-65-200/220 | 22 | 30 | 58 | 57 | 56 | 55 | 54 | ||||||||||||

| MODEL | POWER | Q (m3/h) | 0 | 6 | 9 | 12 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 | 60 | 72 | 90 | 108 | 114 | 120 | 126 | 132 | ||

| kW | HP | Q (l/min) | 0 | 100 | 150 | 200 | 300 | 333 | 360 | 400 | 450 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 | 1800 | 1900 | 2000 | 2100 | 2200 | ||

| 50-32-125/11 | 1.1 | 1.5 | H (m) | 24 | 21.5 | 20.5 | 19.5 | 16 | 13 | ||||||||||||||||

| 50-32-160/15 | 1.5 | 2 | 29.5 | 27 | 26 | 25 | 21 | 18 | |||||||||||||||||

| 50-32-160/22 | 2.2 | 3 | 37 | 33.5 | 32.5 | 32 | 28.5 | 27 | |||||||||||||||||

| 50-32-200/30 | 3 | 4 | 45 | 41 | 40 | 38 | 34 | 32 | |||||||||||||||||

| 50-32-200/40 | 4 | 5.5 | 55 | 51 | 50 | 49 | 46 | 45 | 43 | ||||||||||||||||

| 65-50-125/15 | 1.5 | 2 | 20 | 19 | 18 | 17 | 16.5 | 15 | 14 | 12.5 | 10 | ||||||||||||||

| 65-50-125/22 | 2.2 | 3 | 26 | 23.5 | 22.5 | 22 | 21.5 | 21 | 20.5 | 19.5 | 16.5 | ||||||||||||||

| 65-50-160/30 | 3 | 4 | 31 | 29 | 27.5 | 27 | 26.5 | 25.5 | 25 | 24 | 22 | 19 | |||||||||||||

| 65-50-160/40 | 4 | 5.5 | 39 | 35.5 | 34.5 | 34 | 33.5 | 32.5 | 32 | 31 | 29 | 26 | |||||||||||||

| 65-40-200/55 | 5.5 | 7.5 | 47 | 43 | 42.5 | 42 | 41.5 | 41 | 40.5 | 39 | 37 | 33 | |||||||||||||

| 65-40-200/75 | 7.5 | 10 | 57 | 53 | 52.5 | 52 | 51 | 50 | 49 | 48 | 46.5 | 44.5 | |||||||||||||

| 80-65-125/30 | 3 | 4 | 22.5 | 20 | 19.5 | 19 | 18.5 | 17.5 | 16 | 13 | 9 | ||||||||||||||

| 80-65-125/40 | 4 | 5.5 | 25.5 | 23 | 22.5 | 22 | 21.5 | 20.5 | 20 | 17 | 13.5 | ||||||||||||||

| 80-65-160/55 | 5.5 | 7.5 | 33 | 29.5 | 29 | 28.5 | 28 | 27 | 26 | 24 | 20 | ||||||||||||||

| 80-65-160/75 | 7.5 | 10 | 39 | 36 | 35 | 34.5 | 34 | 33.5 | 32.5 | 29 | 24 | ||||||||||||||

| 80-50-200/92 | 9.2 | 12.5 | 53 | 48 | 47.5 | 46.5 | 44.5 | 39.5 | 34 | ||||||||||||||||

| 80-50-200/110 | 11 | 15 | 57.5 | 53 | 51 | 50.5 | 50 | 47 | 41 | ||||||||||||||||

| 100-80-125/40 | 4 | 5.5 | 20 | 17.5 | 16.5 | 15.5 | 14 | 12 | 7 | ||||||||||||||||

| 100-80-125/55 | 5.5 | 7.5 | 23 | 21.5 | 20.5 | 20 | 18 | 16 | 12 | 7.5 | |||||||||||||||

| 100-80-125/75 | 7.5 | 10 | 29 | 27.5 | 26.5 | 25.5 | 23.5 | 21.5 | 17.5 | 13 | 12 | ||||||||||||||

| 100-80-160/92 | 9.2 | 12.5 | 33 | 31 | 30 | 28 | 26 | 23 | |||||||||||||||||

| 100-80-160/110 | 11 | 15 | 38.5 | 36 | 35 | 33 | 31 | 28 | |||||||||||||||||

| 100-65-200/150 | 15 | 20 | 47 | 44 | 43 | 41 | 39 | 36 | 32 | 30 | 28 | 26 | 23 | ||||||||||||

| 100-65-200/185 | 18.5 | 25 | 53 | 51 | 50 | 49 | 48 | 45 | 41 | 39 | 37 | 35 | 33 | ||||||||||||

| 100-65-200/220 | 22 | 30 | 58 | 57 | 56 | 55 | 54 | 51 | 47 | 45.5 | 44 | 42 | 40 | ||||||||||||

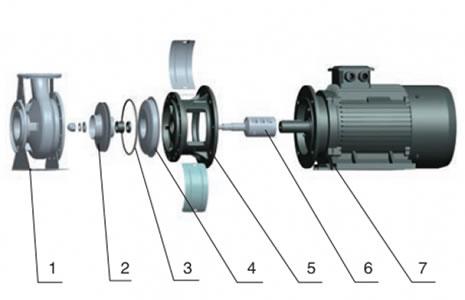

| No. | Part | Material |

| 1 | Pump body | AISI 304 |

| 2 | Impeller | AISI 304 |

| 3 | Mechanical seal | |

| 4 | Rear cover | AISI 304 |

| 5 | Support | HT 200 |

| 6 | Pump shaft | AISI 304/45# |

| 7 | Motor |

LEO is a listed company in China (stock code 002131), LEO is a leading stainless steel standard centrifugal pump manufacturer only offers high quality pumps. LEO has made millions of pumps now used in more than 140 countries, and is offering commercial water pumps, submersible pumps, wastewater pumps with custom solutions. LEO centrifugal water pumps can meet you any requires in commercial pumping systems.

Leave your message here, we will contact with you within one working day.