- Home

- Commercial Pumps

- End Suction Centrifugal Pump

- LEP LEN End Suction Centrifugal Pump

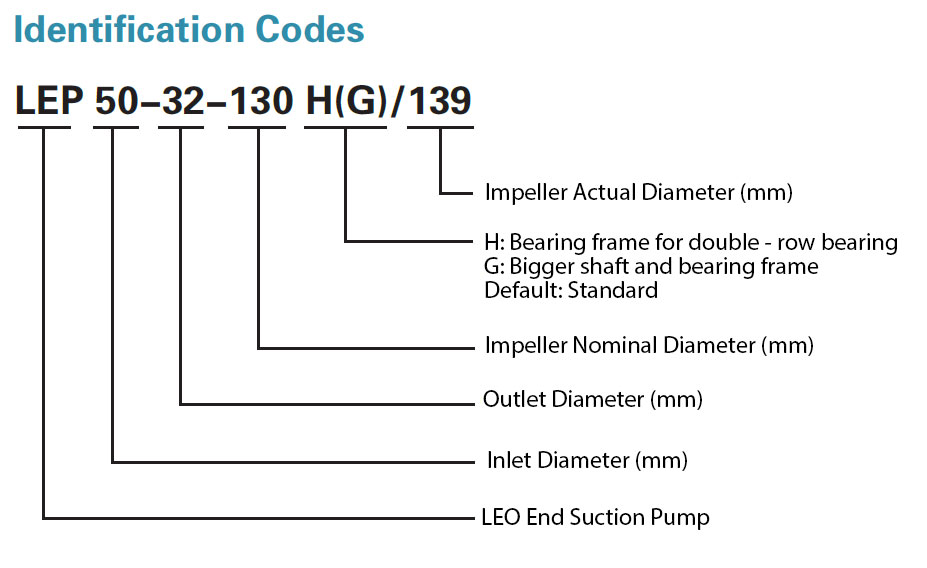

LEP LEN End Suction Centrifugal Pump

Application of LEP LEN End Suction Centrifugal Pump

-Water supply systems

-Pressure boosting

-Heating systems for commercial buildings and district heating

-Cooling plants for industrial processing and air-conditioning units

-General transport for industrial processes

-Firefighting system

Working Conditions of LEP LEN End Suction Centrifugal Pump

The pump design complies with BS EN 733/DIN 24255 standards

Conveying medium: Low viscosity, non-inflammable and non-explosive liquids with no solid particles or fibers

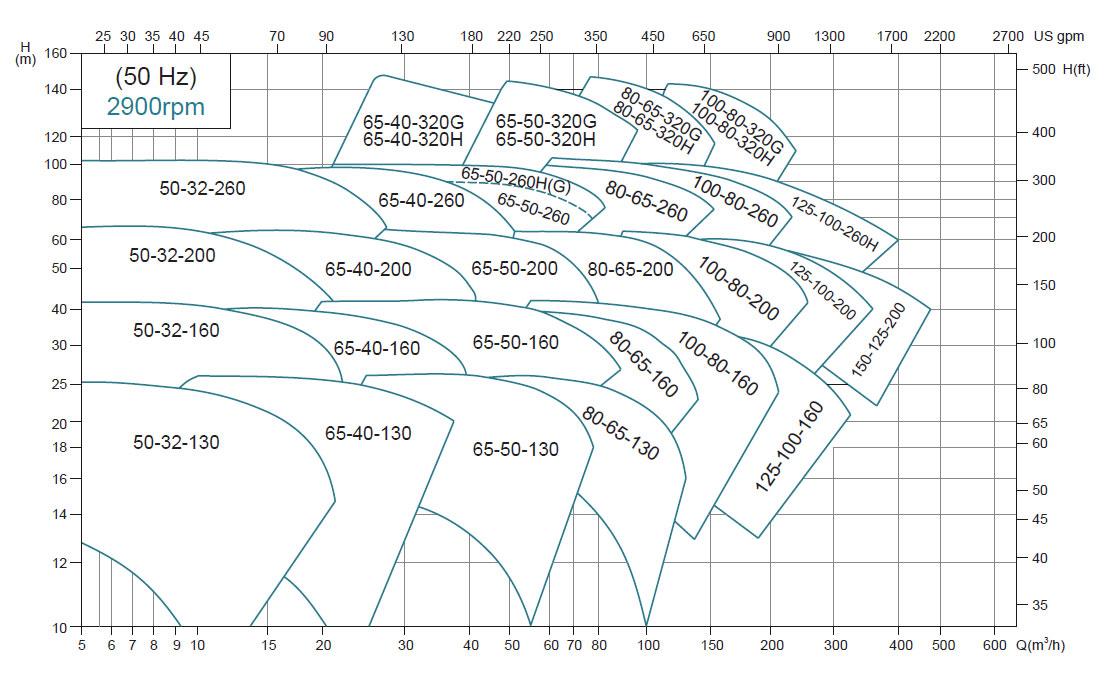

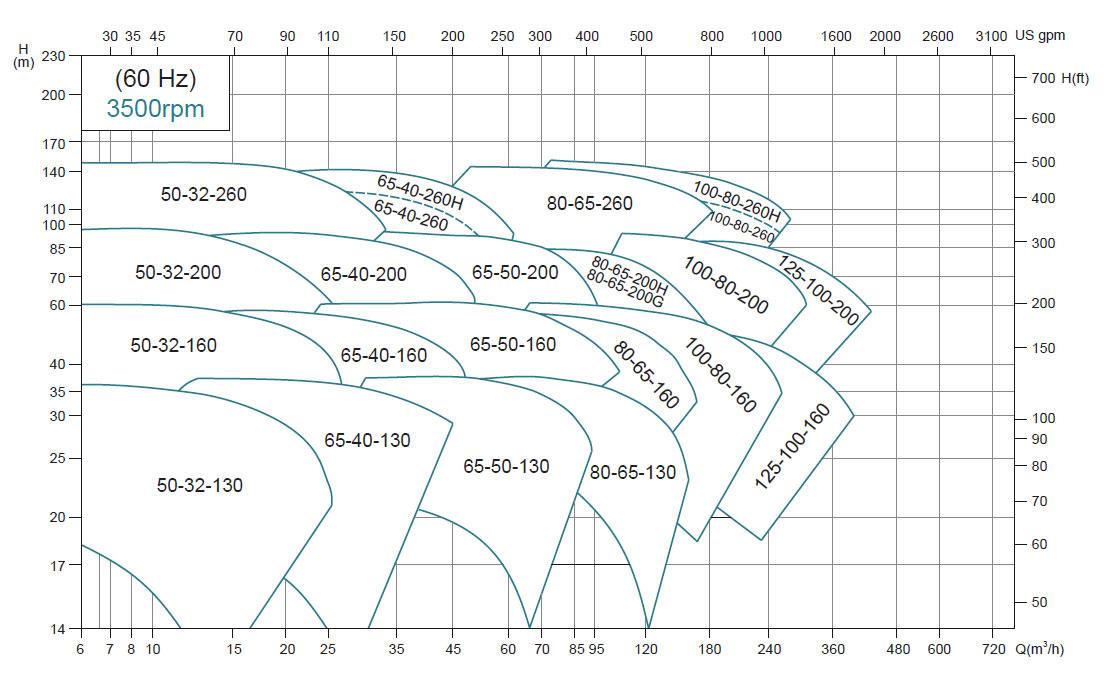

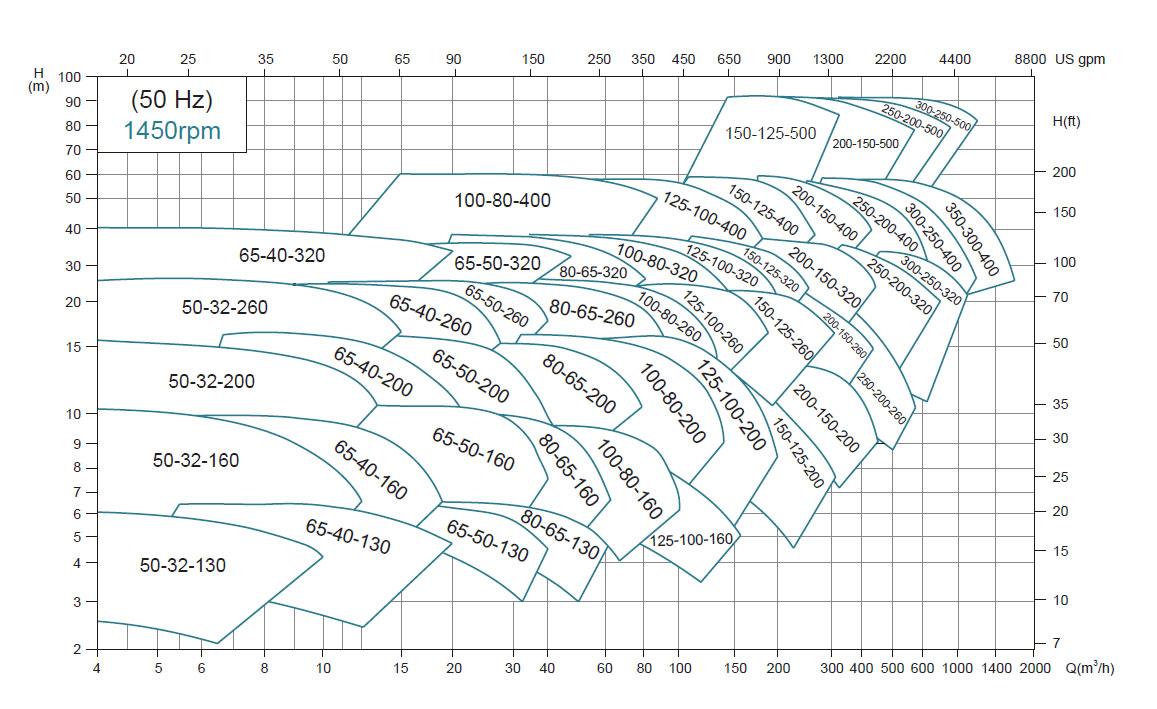

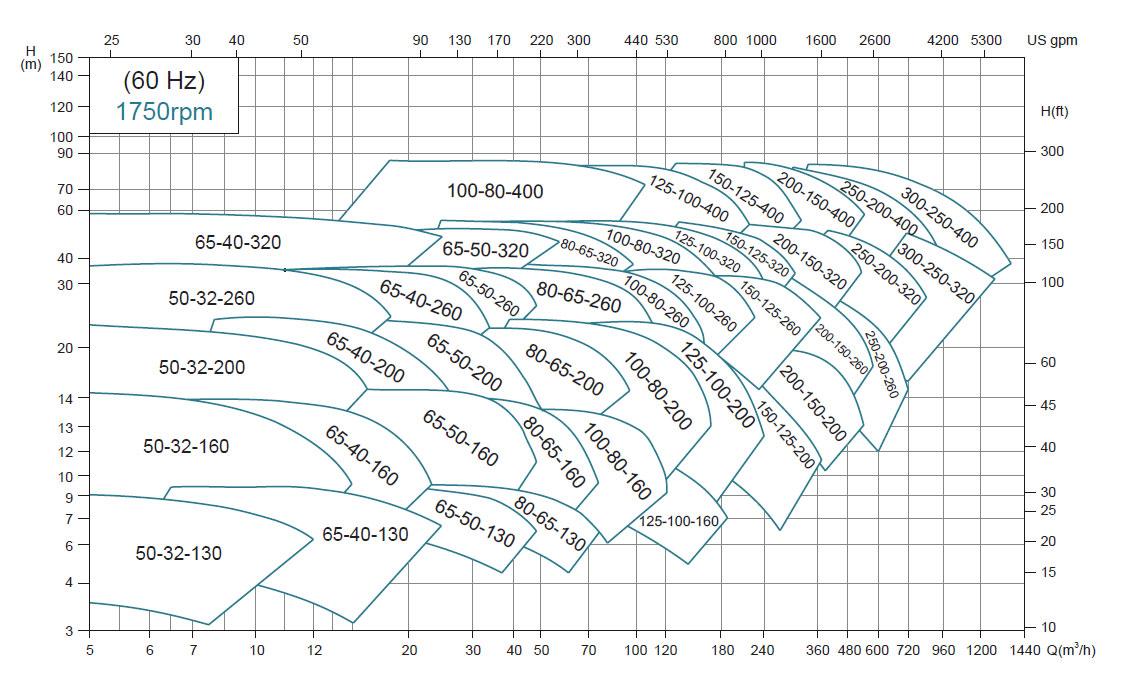

Speed: 1450/2900 rpm at 50 Hz, 1750/3500 rpm at 60 Hz

Flow range: 0.5 - 440 l/s

Head range: 2 - 152 m

Max. liquid temperature: 105°C

Liquid pH value: 4 - 10

Max. operation pressure: 10 bar, 16 bar on request

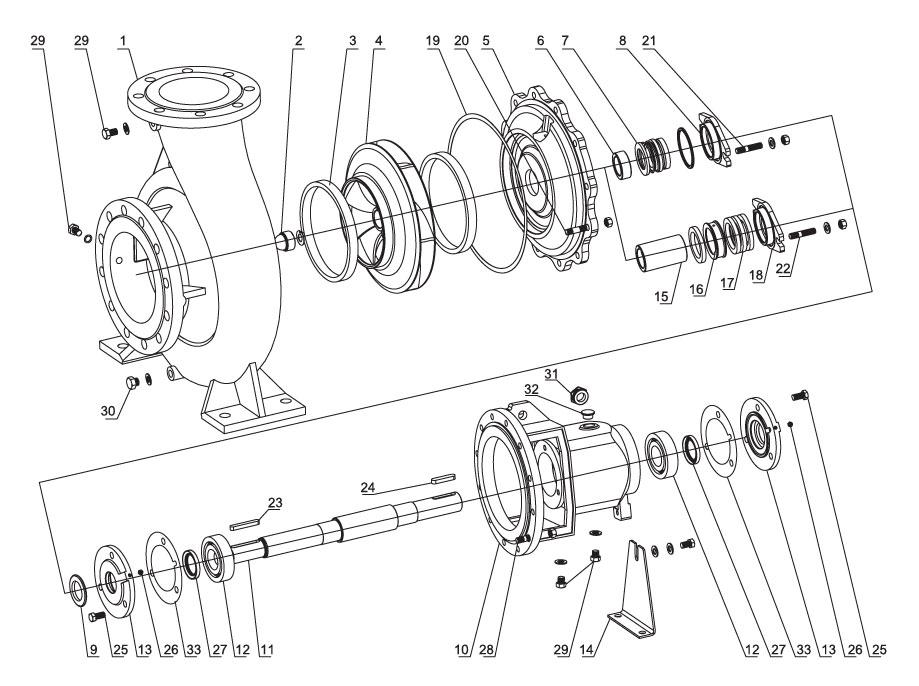

| NO. | Part | Material |

| 1 | Pump casing | Cast Iron Ductile Iron 304/316 |

| 2 | Impeller nut | |

| 3 | Wear ring | |

| 4 | Impeller | Brass/Bronze Cast Iron 304/316 |

| 5 | Casing cover | |

| 6 | Shaft spacer | |

| 7 | Mechanical Seal | |

| 8 | Seal cover | |

| 9 | Rubber slinger | |

| 10 | Bearing frame | |

| 11 | Shaft | 304/316/1045 |

| 12 | Bearing | |

| 13 | Bearing cover | |

| 14 | Support foot | |

| 15 | Packing sleeve | Bronze |

| 16 | Packing seal cage | |

| 17 | Gland packing | |

| 18 | Gland cover | |

| 19 | Casing gasket | |

| 20 | Nut | |

| 21 | Nut | |

| 22 | Nut | |

| 23 | Key | |

| 24 | Key | |

| 25 | Bolt | |

| 26 | Oil nipple | |

| 27 | Oil seal | |

| 28 | Nut | |

| 29 | Washer | |

| 30 | Washer | |

| 31 | Oil scale | |

| 32 | Oil cover | |

| 33 | Bearing Cover Gasket |

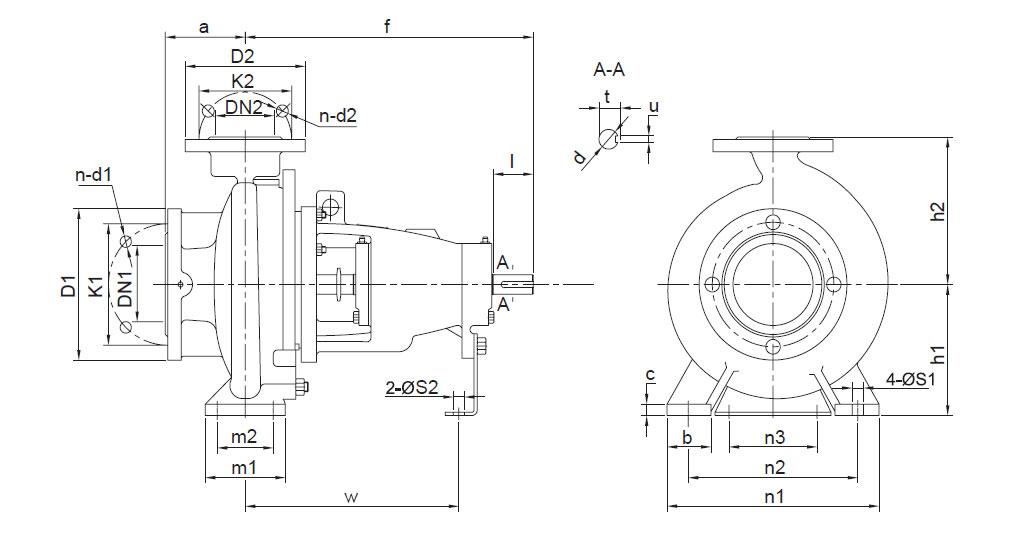

| Model | Bearing ID (mm) | DN2 | DN1 | a | f | h1 | h2 | b | c | n3 | m1 | m2 | n1 | n2 | S1 | S2 | w | d | l | t | u | Weight (kg) | |

| LEP50-32-130 | 25 | 32 | 50 | 80 | 360 | 112 | 140 | 50 | 14 | 100 | 100 | 70 | 190 | 140 | 14 | 14 | 267 | 24 | 50 | 27 | 8 | 29 | |

| LEP50-32-160 | 132 | 160 | 240 | 190 | 35 | ||||||||||||||||||

| LEP50-32-200 | 160 | 180 | 110 | 47 | |||||||||||||||||||

| LEP50-32-260 | 100 | 180 | 225 | 65 | 125 | 95 | 320 | 250 | 58 | ||||||||||||||

| LEP65-40-130 | 25 | 40 | 65 | 80 | 360 | 112 | 140 | 50 | 14 | 100 | 100 | 70 | 210 | 160 | 14 | 14 | 31 | ||||||

| LEP65-40-160 | 132 | 160 | 240 | 190 | 34 | ||||||||||||||||||

| LEP65-40-200 | 100 | 160 | 180 | 110 | 265 | 212 | 45 | ||||||||||||||||

| LEP65-40-260(H) | 180 | 225 | 65 | 125 | 95 | 320 | 250 | 61 | |||||||||||||||

| LEP65-40-320 | 35 | 125 | 470 | 200 | 250 | 345 | 260 | 342 | 32 | 80 | 35 | 10 | 94 | ||||||||||

| LEP65-40-320(H) | 200 | 250 | 107 | ||||||||||||||||||||

| LEP65-40-320G | 45 | 526 | 200 | 250 | 367 | 42 | 110 | 45 | 12 | 105 | |||||||||||||

| LEP65-50-130 | 25 | 50 | 100 | 360 | 132 | 160 | 50 | 100 | 100 | 70 | 240 | 190 | 267 | 24 | 50 | 27 | 8 | 35 | |||||

| LEP65-50-160 | 160 | 180 | 110 | 265 | 212 | 39 | |||||||||||||||||

| LEP65-50-200 | 160 | 200 | 49 | ||||||||||||||||||||

| LEP65-50-260(H) | 180 | 225 | 65 | 125 | 95 | 320 | 250 | 68 | |||||||||||||||

| LEP65-50-260G | 35 | 470 | 180 | 225 | 344 | 32 | 80 | 35 | 10 | 65 | |||||||||||||

| LEP65-50-320(H) | 125 | 225 | 280 | 18 | 345 | 280 | 342 | 113 | |||||||||||||||

| LEP65-50-320G | 45 | 50 | 65 | 125 | 526 | 225 | 280 | 65 | 18 | 125 | 95 | 367 | 42 | 110 | 45 | 12 | 105 | ||||||

| LEP80-65-130 | 25 | 65 | 80 | 100 | 360 | 160 | 180 | 14 | 125 | 95 | 280 | 212 | 267 | 24 | 50 | 27 | 8 | 41 | |||||

| LEP80-65-160 | 160 | 200 | 47 | ||||||||||||||||||||

| LEP80-65-200(H) | 180 | 225 | 320 | 250 | 55 | ||||||||||||||||||

| LEP80-65-200G | 35 | 465 | 180 | 225 | 339 | 32 | 80 | 35 | 10 | 60 | |||||||||||||

| LEP80-65-260 | 470 | 200 | 250 | 80 | 15 | 160 | 120 | 360 | 280 | 18 | 342 | 87 | |||||||||||

| LEP80-65-320(H) | 125 | 225 | 280 | 18 | 400 | 315 | 110 | ||||||||||||||||

| LEP80-65-320G | 45 | 526 | 225 | 280 | 18 | 367 | 42 | 110 | 45 | 12 | 120 | ||||||||||||

| LEP100-80-160 | 25 | 80 | 100 | 530 | 180 | 225 | 65 | 14 | 125 | 95 | 320 | 250 | 14 | 267 | 24 | 50 | 27 | 8 | 53 | ||||

| LEP100-80-200 | 35 | 470 | 180 | 250 | 15 | 345 | 280 | 342 | 32 | 80 | 35 | 10 | 76 | ||||||||||

| LEP100-80-260(H) | 200 | 280 | 80 | 160 | 120 | 400 | 315 | 18 | 95 | ||||||||||||||

| LEP100-80-320(H) | 250 | 315 | 16 | 116 | |||||||||||||||||||

| LEP100-80-320G | 45 | 526 | 250 | 315 | 16 | 367 | 42 | 110 | 45 | 12 | 130 | ||||||||||||

| LEP100-80-400 | 530 | 280 | 355 | 83 | 18 | 440 | 340 | 370 | 160 | ||||||||||||||

| LEP125-100-160 | 35 | 100 | 125 | 470 | 200 | 250 | 80 | 15 | 360 | 280 | 342 | 32 | 80 | 35 | 10 | 87 | |||||||

| LEP125-100-200 | 35 | 200 | 280 | 80 | 16 | 84 | |||||||||||||||||

| LEP125-100-260(H) | 140 | 225 | 280 | 400 | 315 | 102 | |||||||||||||||||

| LEP125-100-320 | 250 | 315 | 118 | ||||||||||||||||||||

| LEP125-100-400 | 45 | 530 | 280 | 355 | 100 | 20 | 200 | 150 | 500 | 400 | 23 | 370 | 42 | 110 | 45 | 12 | 176 | ||||||

| LEP150-125-200 | 35 | 125 | 150 | 470 | 250 | 315 | 80 | 16 | 160 | 120 | 400 | 315 | 18 | 342 | 32 | 80 | 35 | 10 | 112 | ||||

| LEP150-125-260 | 250 | 355 | 117 | ||||||||||||||||||||

| LEP150-125-320 | 45 | 530 | 280 | 355 | 100 | 18 | 200 | 150 | 500 | 400 | 23 | 370 | 42 | 110 | 45 | 12 | 155 | ||||||

| LEP150-125-400 | 160 | 315 | 400 | 178 | |||||||||||||||||||

| LEP150-125-500 | 55 | 670 | 355 | 450 | 25 | 550 | 450 | 500 | 48 | 110 | 51 | 14 | 300 | ||||||||||

| LEP200-150-200 | 35 | 150 | 200 | 555 | 280 | 400 | 18 | 400 | 315 | 342 | 32 | 80 | 35 | 10 | 132 | ||||||||

| LEP200-150-260 | 45 | 530 | 250 | 355 | 450 | 350 | 370 | 42 | 110 | 45 | 12 | 163 | |||||||||||

| LEP200-150-320 | 280 | 400 | 550 | 450 | 170 | ||||||||||||||||||

| LEP200-150-400 | 315 | 450 | 207 | ||||||||||||||||||||

| LEP200-150-500 | 55 | 180 | 670 | 375 | 500 | 22 | 500 | 46 | 51 | 14 | 330 | ||||||||||||

| LEP250-200-260 | 45 | 200 | 250 | 555 | 315 | 450 | 20 | 28 | 392 | 42 | 45 | 12 | 219 | ||||||||||

| LEP250-200-320 | 55 | 670 | 315 | 480 | 120 | 220 | 170 | 600 | 480 | 505 | 48 | 51 | 14 | 286 | |||||||||

| LEP250-200-400 | 335 | 480 | 250 | 328 | |||||||||||||||||||

| LEP250-200-500 | 65 | 200 | 250 | 200 | 720 | 425 | 560 | 100 | 22 | 140 | 200 | 150 | 660 | 560 | 23 | 19 | 515 | 60 | 140 | 64 | 18 | 450 | |

| LEP300-250-320 | 55 | 250 | 300 | 220 | 691 | 355 | 520 | 150 | 26 | 110 | 250 | 200 | 660 | 510 | 28 | 14 | 525 | 48 | 110 | 51 | 14 | 366 | |

| LEP300-250-400 | 682 | 400 | 560 | 516 | 396 | ||||||||||||||||||

| LEP300-250-500 | 65 | 250 | 300 | 200 | 720 | 450 | 670 | 120 | 32 | 140 | 240 | 190 | 750 | 650 | 23 | 19 | 515 | 60 | 140 | 64 | 18 | 550 | |

| LEP350-300-400 | 65 | 300 | 350 | 300 | 720 | 425 | 670 | 120 | 30 | 250 | 190 | 760 | 660 | 30 | 19 | 515 | 60 | 140 | 64 | 18 | 550 |

| (ISO7005.2 DIN2501 PN16 GB/T17241.6 PN1.6) | |||||||||||||

| DN1/DN2 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| D1/D2 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 |

| K1/K2 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 |

| n-d1/n-d2 | 4-φ18 | 4-φ18 | 4-φ18 | 4-φ18 | 8-φ18 | 8-φ18 | 8-φ18 | 8-φ22 | 12-φ22 | 12-φ26 | 12-φ26 | 16-φ26 | 16-φ30 |

LEO is a leading end suction centrifugal pump manufacturer only offers high quality pumps. LEO has made millions of water and sewage pumps now used in more than 140 countries. LEO centrifugal water pumps can meet you any requires in commercial pumping systems.

Leave your message here, we will contact with you within one working day.