- Home

- Commercial Pumps

- Submersible Sewage Pump

- Cast Iron Submersible Sewage Pump

- WQ Submersible Sewage Pump

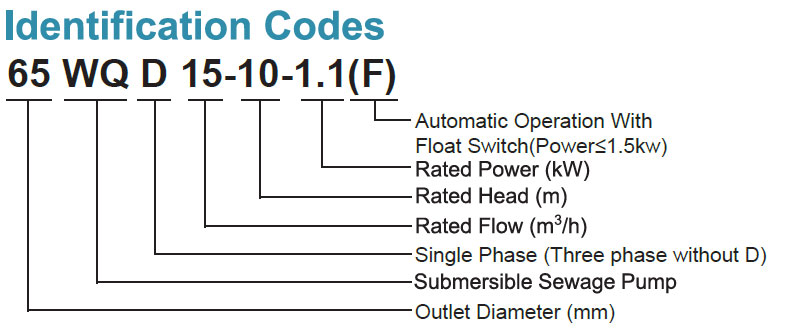

WQ Submersible Sewage Pump

Application

- Wastewater drainage in factories, construction sites and commercial facilities.

- Drainage system in municipal sewage treatment plants.

- Drainage station in residential quarters.

- Municipal projects.

- Methane pools and field irrigation in countryside.

WQ Submersible Sewage Pump Features

- Max. Immersion depth: 25 m.

- Max. liquid temperature: +40℃.

- Liquid PH value: 5-9.

- Max. liquid density: 1.2x10³kg/m³

WQ Submersible Sewage Pump Motor Features

- Copper winding.

- Insulation class: B.

- Protection class: IP68.

| Model | Voltage | Motor Power | Outlet | Guide Rail Fitting | Max. flow | Max. Head | Speed | Impeller passage | ||

| V | KW | HP | in | m³ /h | m | r.p.m | mm | |||

| 50WQ10-10-0.75 | 380 | 0.75 | 1 | 2 | 50-50 | 28 | 13 | 3000 | 25 | |

| 50WQD10-10-0.75 | 220 | 0.75 | 1 | 2 | 50-50 | 28 | 13 | 3000 | 25 | |

| 50WQ8-16-1.1 | 380 | 1.1 | 1.5 | 2 | 50-50 | 25 | 19 | 3000 | 20 | |

| 50WQD8-16-1.1 | 220 | 1.1 | 1.5 | 2 | 50-50 | 25 | 19 | 3000 | 20 | |

| 65WQ15-10-1.1 | 380 | 1.1 | 1.5 | 2 1/2 | 50-65 | 28 | 15 | 3000 | 25 | |

| 65WQD15-10-1.1 | 220 | 1.1 | 1.5 | 2 1/2 | 50-65 | 28 | 15 | 3000 | 25 | |

| 50WQ8-20-1.5 | 380 | 1.5 | 2 | 2 | 50-50 | 25 | 22 | 3000 | 20 | |

| 50WQD8-20-1.5 | 220 | 1.5 | 2 | 2 | 50-50 | 25 | 22 | 3000 | 20 | |

| 65WQ15-15-1.5 | 380 | 1.5 | 2 | 2 1/2 | 50-65 | 35 | 20 | 3000 | 25 | |

| 65WQD15-15-1.5 | 220 | 1.5 | 2 | 2 1/2 | 50-65 | 35 | 20 | 3000 | 25 | |

| 65WQ15-20-2.2 | 380 | 2.2 | 3 | 2 | 50-50 | 38 | 23 | 3000 | 25 | |

| 65WQ25-17-2.2 | 380 | 2.2 | 3 | 2 1/2 | 65-65 | 44 | 22 | 3000 | 25 | |

| 80WQ40-9-2.2 | 380 | 2.2 | 3 | 3 | 65-80 | 65 | 16 | 3000 | 30 | |

| 50WQ15-26-3 | 380 | 3 | 4 | 2 | 50-50 | 47 | 29 | 3000 | 25 | |

| 65WQ25-22-3 | 380 | 3 | 4 | 2 1/2 | 65-65 | 55 | 26 | 3000 | 30 | |

| 80WQ40-13-3 | 380 | 3 | 4 | 3 | 80-80 | 72 | 21 | 3000 | 30 | |

| 100WQ60-9-3 | 380 | 3 | 4 | 4 | 80-100 | 88 | 19 | 3000 | 30 | |

| 65WQ25-28-4 | 380 | 4 | 5.5 | 2 1/2 | 65-65 | 55 | 32 | 3000 | 25 | |

| 80WQ40-18-4 | 380 | 4 | 5.5 | 3 | 80-80 | 80 | 24 | 3000 | 30 | |

| 100WQ60-13-4 | 380 | 4 | 5.5 | 4 | 80-100 | 89 | 24 | 3000 | 30 | |

| 50WQ15-40-5.5 | 380 | 5.5 | 7.5 | 2 | 50-50 | 50 | 43 | 3000 | 25 | |

| 80WQ30-30-5.5 | 380 | 5.5 | 7.5 | 3 | 80-80 | 47 | 37 | 3000 | 30 | |

| 100WQ65-15-5.5 | 380 | 5.5 | 7.5 | 4 | 100-100A | 108 | 25 | 3000 | 30 | |

| 100WQ56-22-7.5 | 380 | 7.5 | 10 | 4 | 100-100A | 90 | 31 | 3000 | 35 | |

| 150WQ100-10-7.5 | 380 | 7.5 | 10 | 6 | 150-150 | 140 | 20 | 3000 | 35 | |

| 100WQ65-15-5.5(4P) | 380 | 5.5 | 7.5 | 4 | 100-100 | 145 | 21 | 1500 | 55 | |

| 150WQ110-10-5.5(4P) | 380 | 5.5 | 7.5 | 6 | 150-150 | 200 | 16 | 1500 | 55 | |

| 100WQ100-15-7.5(4P) | 380 | 7.5 | 10 | 4 | 100-100 | 170 | 21 | 1500 | 55 | |

| 150WQ150-10-7.5(4P) | 380 | 7.5 | 10 | 6 | 150-150 | 220 | 16 | 1500 | 75 | |

| 100WQ100-25-11(4P) | 380 | 11 | 15 | 4 | 100-100 | 180 | 26 | 1500 | 50 | |

| 150WQ130-15-11(4P) | 380 | 11 | 15 | 6 | 150-150 | 270 | 20 | 1500 | 50 | |

| 200WQ300-7-11(4P) | 380 | 11 | 15 | 8 | 200-200 | 360 | 18 | 1500 | 65 | |

| 100WQ100-30-15(4P) | 380 | 15 | 20 | 4 | 100-100 | 190 | 32 | 1500 | 50 | |

| 150WQ130-20-15(4P) | 380 | 15 | 20 | 6 | 150-150 | 300 | 23 | 1500 | 50 | |

| 200WQ250-11-15(4P) | 380 | 15 | 20 | 8 | 200-200 | 380 | 22 | 1500 | 65 | |

| 150WQ180-20-18.5(4P) | 380 | 18.5 | 25 | 6 | 150-150 | 300 | 26 | 1500 | 50 | |

| 200WQ250-15-18.5(4P) | 380 | 18.5 | 25 | 8 | 200-200 | 400 | 25 | 1500 | 65 | |

| 150WQ180-25-22(4P) | 380 | 22 | 30 | 6 | 150-150 | 330 | 28 | 1500 | 50 | |

| 200WQ300-15-22(4P) | 380 | 22 | 30 | 8 | 200-200 | 450 | 28 | 1500 | 65 | |

| 150WQ180-30-30(4P) | 380 | 30 | 40 | 6 | 150-150 | 350 | 38 | 1500 | 70 | |

| 200WQ250-22-30(4P) | 380 | 30 | 40 | 8 | 200-200 | 500 | 34 | 1500 | 70 | |

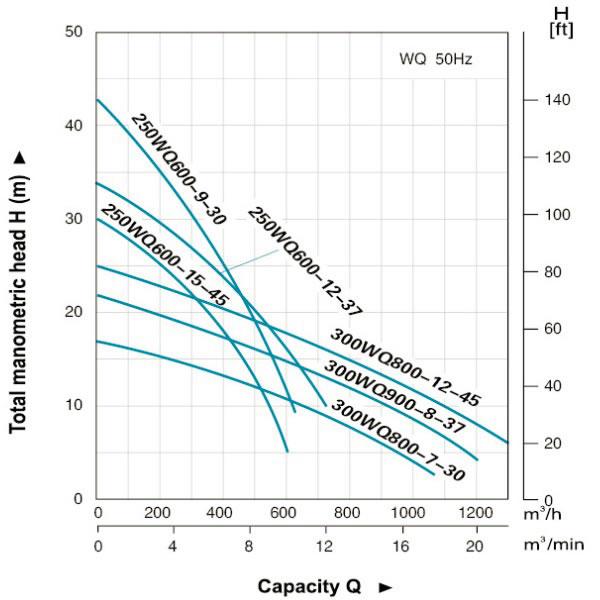

| 250WQ600-9-30(4P) | 380 | 30 | 40 | 10 | 250-250 | 600 | 28 | 1500 | 70 | |

| 300WQ800-7-30(4P) | 380 | 30 | 40 | 12 | 300-300 | 1000 | 18 | 1500 | 80 | |

| 150WQ160-45-37(4P) | 380 | 37 | 50 | 6 | 150-150 | 380 | 43 | 1500 | 70 | |

| 200WQ350-25-37(4P) | 380 | 37 | 50 | 8 | 200-200 | 500 | 38 | 1500 | 70 | |

| 250WQ600-12-37(4P) | 380 | 37 | 50 | 10 | 250-250 | 720 | 32 | 1500 | 70 | |

| 300WQ900-8-37(4P) | 380 | 37 | 50 | 12 | 300-300 | 1200 | 22 | 1500 | 80 | |

| 200WQ380-28-45(4P) | 380 | 45 | 60 | 8 | 200-200 | 800 | 38 | 1500 | 70 | |

| 250WQ600-15-45(4P) | 380 | 45 | 60 | 10 | 250-250 | 600 | 43 | 1500 | 70 | |

| 300WQ800-12-45(4P) | 380 | 45 | 60 | 12 | 300-300 | 1300 | 25 | 1500 | 80 | |

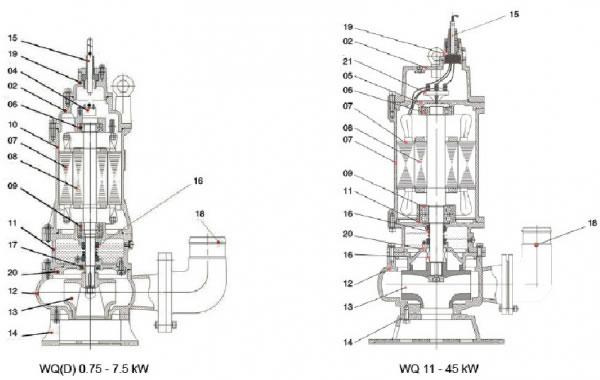

| No. | Part | Material |

| 1 | Handle | Steel |

| 2 | Upper Cover | Cast Iron |

| 3 | Capacitor | |

| 4 | Thermal Protector | |

| 5 | Upper Bearing Seat | Cast Iron |

| 6 | Bering | |

| 7 | Stator | |

| 8 | Rotor | |

| 9 | Bearing | |

| 10 | Motor Body | Cast Iron |

| 11 | Bearing Seat | Cast Iron |

| 12 | Pump Body | Cast Iron |

| 13 | Impeller | Cast Iron |

| 14 | Base | Cast Iron |

| 15 | Cable | |

| 16 | Mechanical Seal | Sic-Sic/Carbon-Ceramic(< 7.5kw) Sic-Sic/Sic-Sic(>7.5kw) |

| 17 | Oil Seal | |

| 18 | Hose Coupling | Cast Iron |

| 19 | Terminal Box | Cast Iron |

| 20 | Seal Bracket | Cast Iron |

| 21 | Wiring Terminal |

LEO is a listed company in China (stock code 002131), LEO is a leading wastewater and sewage water pump manufacturer only offers high quality pumps. LEO has made millions of pumps now used in more than 140 countries, and is offering commercial water pumps, submersible pumps, centrifugal pumps, booster pumps with custom solutions. LEO sewage pumps can meet you any requires in commercial pumping systems.

Leave your message here, we will contact with you within one working day.