- Home

- Domestic Pumps

- Centrifugal Pump

- Centrifugal Pump

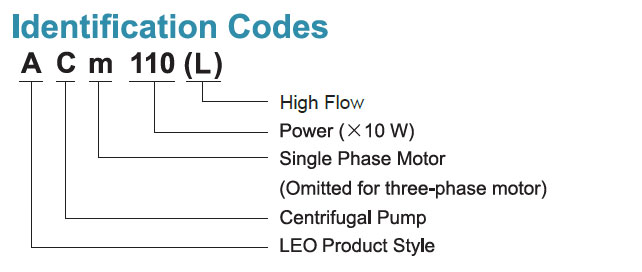

- ACm Centrifugal Pump

ACm Centrifugal Pump

Centrifugal Pump Application

- Centrifugal pump can be used to transfer clean water or other liquids similar to water in physical and chemical properties.

- Suitable for industry use and urban water supply, pressure boosting for high buildings and fire fighting, garden irrigation, long-distance water transferring, heating ventilation and air controlling, circulation and pressure boosting for cold and hot water, and supporting equipment etc.

Centrifugal Pump Features

- Cast iron pump body and support under special anti-rust treatment.

- AISI 304 shaft.

- Max. liquid temperature: +40℃.

- Max. suction: +8m.

ACm Centrifugal Pump Motor Features

- C&U bearing.

- Motor with cooper winding.

- Built-in thermal protector for single phase motor.

- Insulation class: F.

- Protection class: IPX4.

- Max. ambient temperature: +40℃.

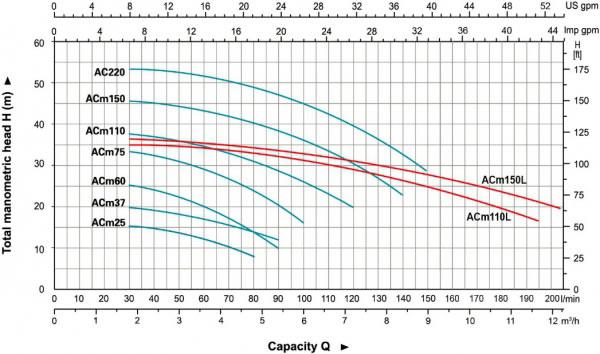

| MODEL | POWER | Q(m³/h) | 0 | 0.6 | 0.9 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.2 | 4.5 | 4.8 | 5.4 | 6 | 6.6 | 7.2 | 7.8 | 8.4 | 9 | 9.6 | 10.8 | 11.7 | 12.6 | ||

| Single Phase | Three Phase | KW | HP | Q(l/min) | 0 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 70 | 75 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 180 | 195 | 200 |

| ˗ | 0.25 | 0.3 | H (m) |

17 | 16.5 | 16.2 | 16 | 15.5 | 14.5 | 13.5 | 12.5 | 10.5 | 9.5 | 8 | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | |

| ˗ | 0.37 | 0.5 | 23 | 21.5 | 21 | 21 | 20.5 | 19.5 | 18 | 17 | 15.5 | 14.5 | 14 | 12 | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ||

| 0.6 | 0.8 | 27 | 26.5 | 26.2 | 26 | 25 | 24.5 | 22.5 | 20 | 17 | 15.5 | 14 | 10 | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | |||

| 0.75 | 1 | 36 | 35 | 34 | 33.5 | 33 | 32 | 31 | 29 | 27 | 26 | 23.5 | 20 | 16 | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | |||

| 1.1 | 1.5 | 40 | 39 | 38 | 38 | 37.5 | 37 | 36 | 35 | 33 | 32 | 31 | 29 | 26 | 23 | 20 | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | ˗ | |||

| 1.5 | 2 | 48 | 47.5 | 47 | 46.5 | 45.5 | 44.5 | 43.5 | 42.5 | 41.5 | 41 | 40.5 | 39 | 37 | 34.5 | 31 | 27 | 22 | ˗ | ˗ | ˗ | ˗ | ˗ | |||

| 2.2 | 3 | 55 | 54.5 | 53 | 53.5 | 53 | 52.5 | 51.5 | 50.5 | 49.5 | 48 | 48.5 | 47 | 45.5 | 43.5 | 40 | 36.5 | 32.5 | 28 | ˗ | ˗ | ˗ | ˗ | |||

| 1.1 | 1.5 | 34.5 | 34.3 | 34.2 | 34.1 | 34 | 33.8 | 33.5 | 33 | 32.5 | 32.3 | 32 | 31 | 30.5 | 29.5 | 28.5 | 27.5 | 26.5 | 25 | 23.5 | 20 | 16.5 | ˗ | |||

| 1.5 | 2 | 37.5 | 37.2 | 37 | 36.9 | 36.6 | 36.2 | 35.8 | 35.4 | 35 | 34.8 | 34.7 | 34 | 33.3 | 32.5 | 31.5 | 30.5 | 29.5 | 28.2 | 27 | 24 | 21 | 19 | |||

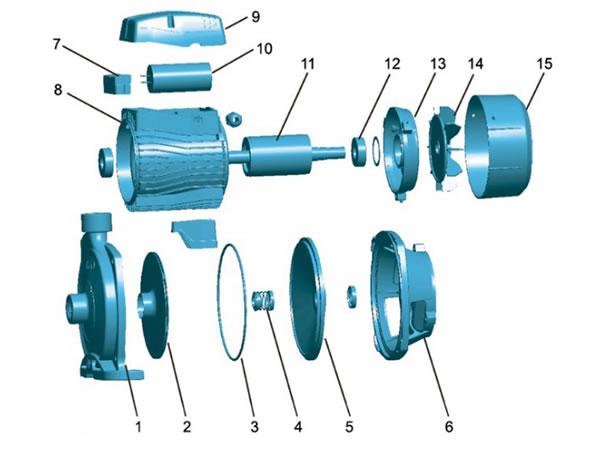

| No. | Part | Material |

| 1 | Pump body | HT 200 |

| 2 | Impeller | AISI 304 Brass |

| 3 | O-ring | NBR |

| 4 | Mechanical seal | Carbon/Ceramic |

| 5 | Support Cover | AISI 304/HT 200 |

| 6 | Support | ZL 102 |

| 7 | Terminal board | PC |

| 8 | Stator | |

| 9 | Terminal box | ABS |

| 10 | Capacitor | |

| 11 | Rotor | |

| 12 | Bearing | |

| 13 | Rear cover | ZL 102 |

| 14 | Fan | PP |

| 15 | Fan Cover | PP |

LEO is a listed company in China (stock code 002131), LEO is a leading centrifugal pump manufacturer only offers high quality pumps. LEO has made millions of pumps now used in more than 140 countries, and is offering residential water pumps, impeller pump, liquid pump, single phase pumps, three phase water pumps with custom solutions. LEO centrifugal water pumps can meet you any requires in domestic pumping systems.

Leave your message here, we will contact with you within one working day.